Surface Mount Technology (SMT) plays a major role in the electronic assembly process. Essegi System has always adopted the most innovative systems, supported by experienced operators and constantly updated to guarantee its customers maximum efficiency and quality of service.

If in SMT assembly “automation” is commonly meant by the speed of execution, maximum precision, and elimination of human error, the promise of Essegi System is much broader and more advanced.

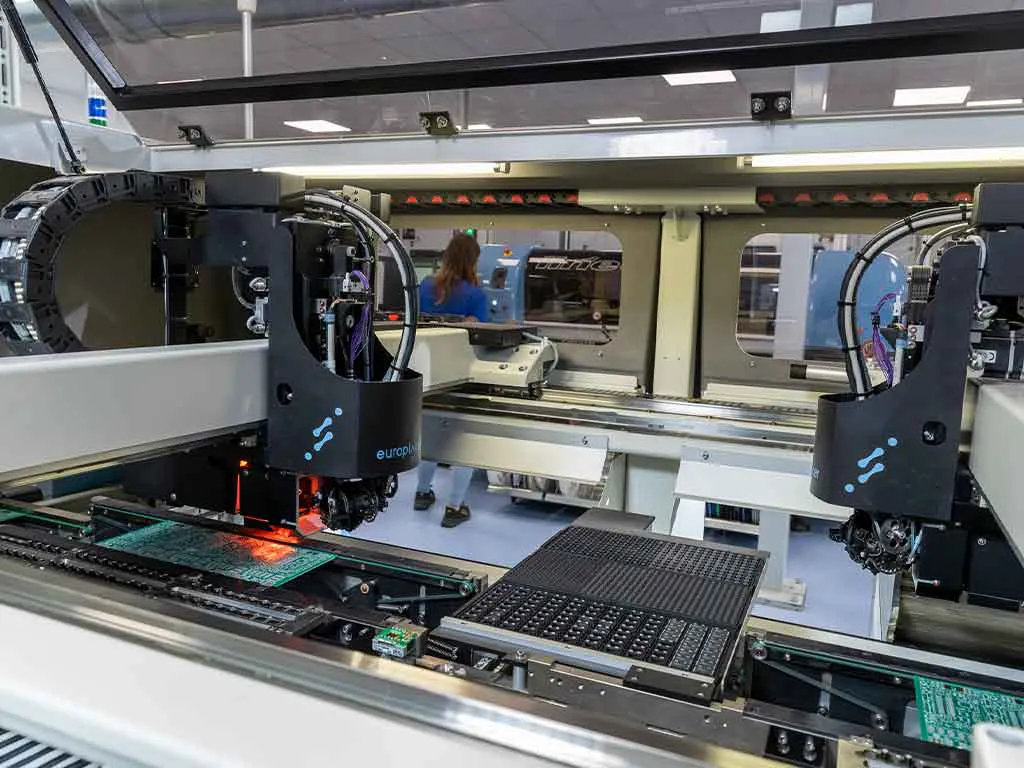

Essegi System Service’s offer can count on 2 high-performance SMT production lines equipped with:

- EKRA screen printing

- Europlacer IIneo+ Pick&Place

- Forced air and vacuum remelting furnace

- Essegi Automation ISM systems supporting kitting

The advantages of our SMT process

Assembly Capacity

30,000 components/h

Precision Assembly

“fine pitch” processors up to 01005

Mounting on Both Sides

Advanced robotic assembly technologies

Welding with an Empty Chamber

Void resolution and pollutant elimination

Procurement and Kitting

With integrated automatic storage systems

Storage and Traceability

Integrated 4.0 management of storage and production systems for complete component traceability, from material acceptance to delivery of the finished product.