Washing and conformal coating are necessary steps before the assembly phase to ensure the complete reliability of the product over time.

Any impurities that settle on the board surface will compromise its functionality over time. This stage of the production process is therefore essential to remove contaminants and ensure complete protection of the board.

Washing

Essegi System is equipped with automated washing systems to remove any impurities or contaminants and ensure perfect adhesion of the conformal coating to the board.

The water-based washing process can be customized to meet customer needs to provide maximum flexibility in component selection.

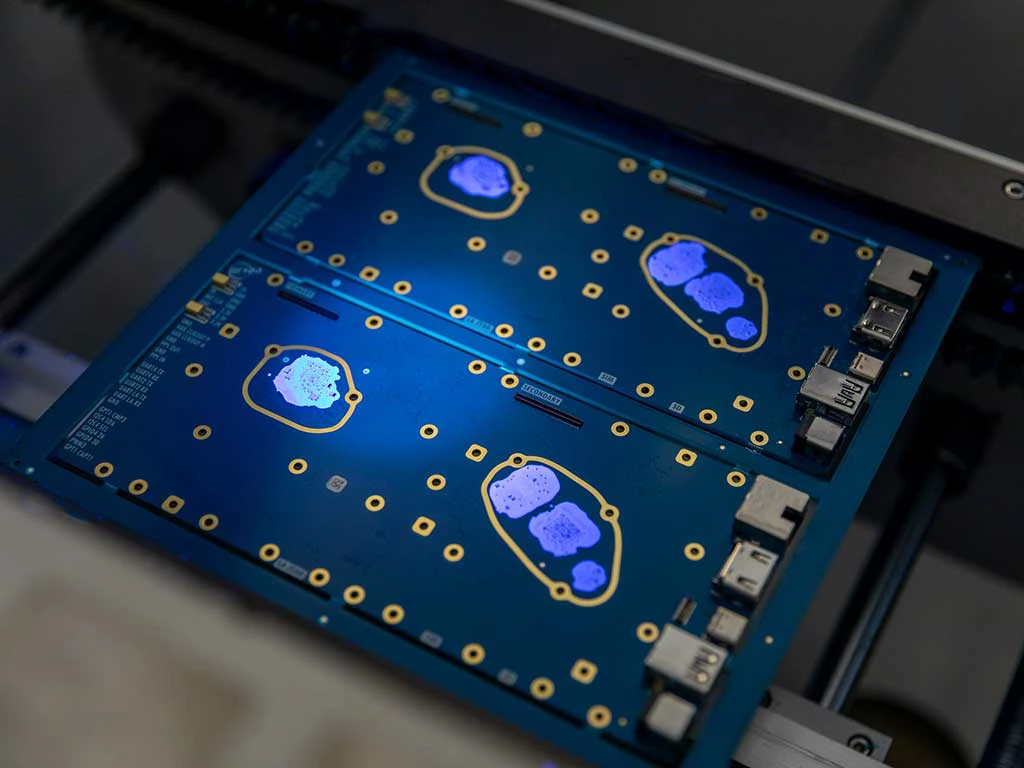

Conformal coating

The conformal coating, or tropicalization treatment, consists of the application of a transparent protective film formed by acrylic resins, which adhere perfectly to the assembled board.

This special processing is carried out completely automatically with precision instruments. The aim is to guarantee the integrity of the assembled product and, above all, to protect it from environmental factors (dust, moisture, production residues, electrostatic currents), guaranteeing its thermal and electrical insulation over time.

For further information